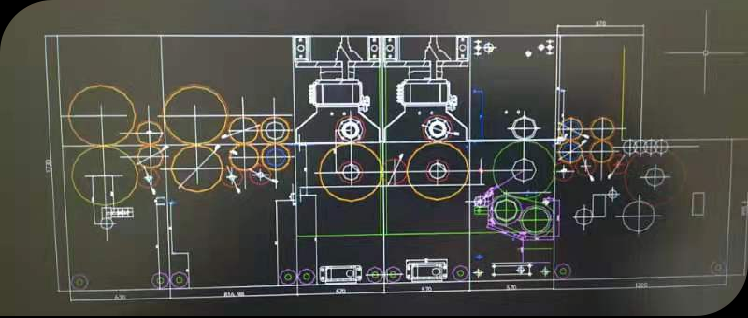

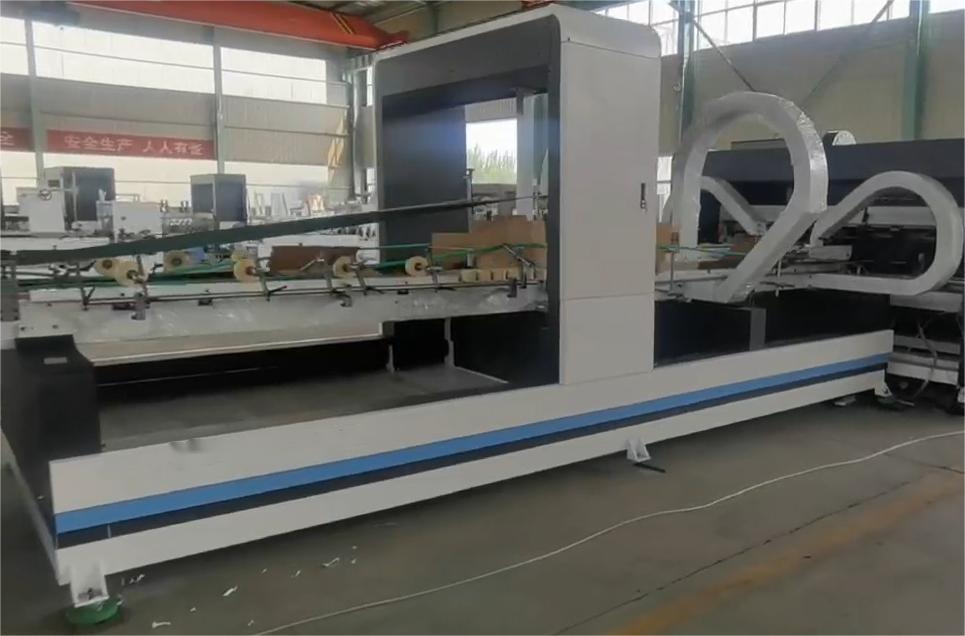

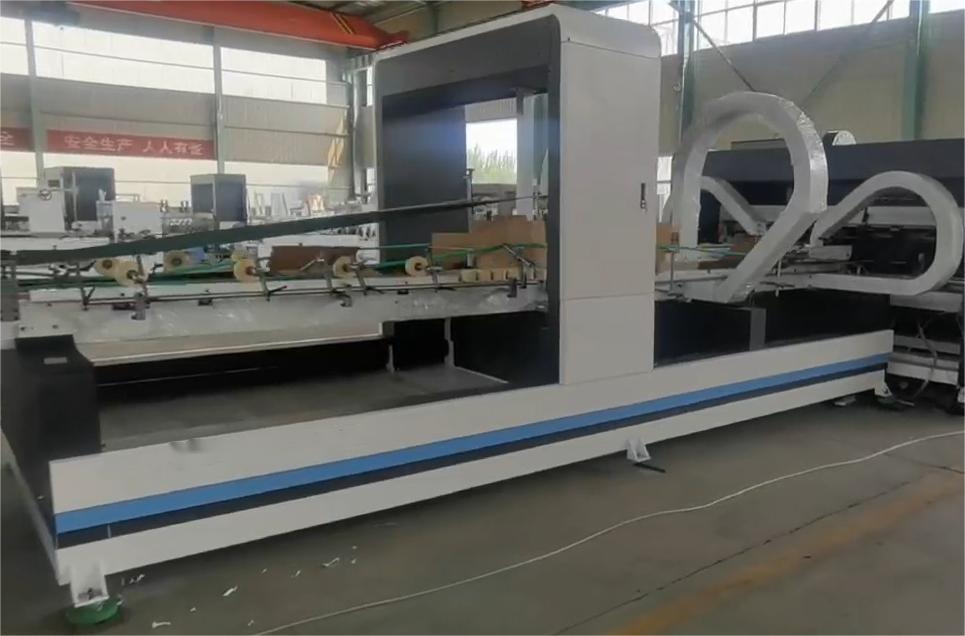

LDX320-900x2400 Lead Edge 5Color Printer Slotter Die Cutter

Online Folder Gluer Machine

Main Technical Parameters:

|

No.

|

Item

|

900*2400

|

|

|

Printing Machine Part

|

|

1

|

Max feeder size

|

900*2400mm

|

|

|

2

|

Max skip feeder size

|

1100*2400mm

|

|

3

|

Max printer size

|

850*2200mm

|

|

4

|

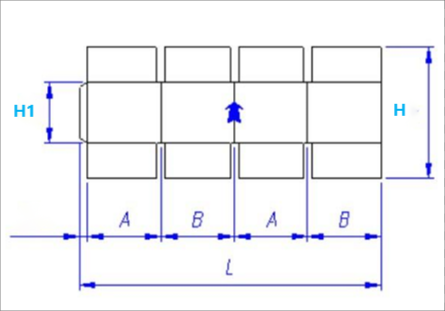

A - B Min. (symmetric slotter)

|

110*110*110*110mm

|

|

5

|

Max die cut size

|

900*2400mm

|

|

6

|

H Min.

|

280mm

|

|

7

|

H Max.

|

900mm

|

|

8

|

H1 Min.

|

40mm

|

|

9

|

L Min.

|

600mm

|

|

10

|

L Max.

|

2400mm

|

|

11

|

Print roller diameter

|

289.6mm

|

|

12

|

Print roller circumference

|

900mm

|

|

13

|

Standard plate thickness

|

7.2mm

|

|

14

|

Cardboard thickness

|

1.5-9mm

|

|

15

|

Design speed

|

320pcs/min

|

|

16

|

Running speed

|

250-280pcs/min

|

|

|

Flute type

|

A-C-B-E-AB-AC-BC-EB-EF

|

|

|

Folder Gluer Part

|

|

1

|

Max feeder size

|

1200*2400mm

|

|

|

2

|

Min feeder size

|

320*750mm

|

|

3

|

Running speed

|

0-150m/min

|

|

4

|

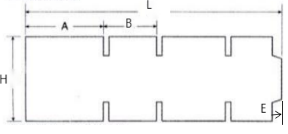

H Min.

|

320mm

|

|

5

|

H Max.

|

1200mm

|

|

6

|

L Min.

|

750mm

|

|

7

|

L Max.

|

2400mm

|

|

8

|

A Min.

|

230mm

|

|

9

|

A Max.

|

750mm

|

|

10

|

B Min.

|

130mm

|

|

11

|

B Max.

|

550mm

|

|

12

|

E

|

30-40mm

|

Main components:

1. Lead-edge feeding part ----------------------- one unit(Independent servo drive)

2. Printing part ------------------ five unit (5ceramic anilox roller,5 doctor blade)

3. Slotter part ------------------------- one unit (full electric touch screen control)

4. Die-cutting part ------------------------ one unit (Independent servo drive)

5. Folder gluer part ------------------------ one unit (servo control stacker)

6. Transmission ------------------------- vacuum transfer, PLC control Totally 9 units.

Machine Features:

- It adopts the computer control system can store up to 5000 orders. 3-5 mins changing the orders quick and convenient.

- All of the transmission gears and rollers adopt good quality steel with heat treatment and grinding.

- All of the units marches with alarm ringing , each unit sets a sudden stop switch to ensure the safety of the operator.

- All drive rollers are high quality steel, hard chrome plated, surface grinding

- The wall plate is high quality steel, which is processed by CNC machining center after stress removal

- Paint spraying process: before painting, parts through the de-rusting - phosphating - spray - paint - baking paint, so that the paint rust, hard surface, paint more durable

- Machine with large screen display table, display the machine printing speed (by pcs/hour), convenient for operating personnel in different directions machine is easy to see the running speed of the machine.

- Lubricating oil automatic balancing device to keep all units of lubricating oil on the same horizontal line

- Automatic zero function.

- Adopt the bottom printing process and full vacuum adsorption transfer.

- The touch screen is use to display the operation and fault description.

- Automat complete paper printer slotter die cutter and folding, deviation correction, pasting glue, servo down type counting and stacking output.

- The gluer unit feeding section adopts vacuum belt to feed paper accurately without skew.

- Adopt gun system smart pasting easy to dry and clean, any gluing scheme can be completed well.

- It is suitable for export packaging and environmental protection packaging, such as beverage box, beer box, instant noodle box, ceramic tile box and other high-grade packaging carton.

Details Of machine:

High speed lead-edge feeding part:

- Leading edge adopt press-free feeding system, independently driven by servo motor.

- Variable frequency drive control of the vacuum blower fan for increased or decreased vacuum suction to match different sizes of paperboard.

- Continuous or skip feeding option with counter.

- Motorized and PLC control of feeder side guides.

- Motorized backstop forward/ backward and up/down position for easy and quick adjustment.

- Main motor protection from starting up when units are not fully closed and locked.

- Duct exhaust device.

- Dust removal equipment with dust absorption blower. Automatic zero returning.

- Touch screen can be input the production plan and show the produce sheets number, once plan is finish, the system stops the feeding part warns.

- Electric gap adjustment.

- PLC control with digital display of rear box to set width and height of the cardboard.

- The traveling shaft is equipped with a friction clutch to avoid damage to the machine due to misoperation.

Printing part :

- Printing Roller

- The surface of the printing roller is ground and hard chrome plated.

- The balance is correct and the operation is stable.

- It is equipped with rotary roll type plate loading system, automatic locking, backstop, and deviation correction function.

- Full version hanging plate hook, applicable to 10mm hanging plate strip.

- Loading and unloading the printing board, and the foot switch electrically controls the forward and reverse rotation.

- Printing Pressure Roller

- In the vacuum suction box, the vacuum adsorption conveying paperboard

- Vacuum absorption is adopted to transport the cardboard. The cardboard can pass through the printing section without the use of a paper pulling ring, and the cardboard can be transported very accurately to improve the chromatic accuracy. (The valve have 3 gear is adjust)

- The surface of the embossing roller is ground and hard chrome plated.

- The balance is correct and the operation is stable.

- The gap between printing plate rollers is controlled by PLC.

- Anilox Roller

- Ceramic Anilox roll with doctor blade system. ANILOX 380 - 380- 400 - 400- 450 lines. Ceramic anilox roller: the surface of the steel pipe is covered with ceramic grinding and laser engraving anilox.

- When the paper feeding stops, the anilox roller will automatically leave the plate surface, extending the service life of the plate.

- The anilox roller is driven by an independent motor and has an automatic idling system to prevent ink from drying up

- The dots are consistent and the ink is evenly applied

- It is more wear-resistant than steel anilox roll and has a long service life

- The clearance with the printing roller is adjusted by PLC control.

- Doctor Blade

- Single scraper system is adopted.

- The single scraper acts on the ceramic anilox roller Compared with rubber roller inking system, it can greatly reduce the waste of ink, and significantly improve the quality of monochrome dot and dot stack printing.

- The pneumatic bidirectional diaphragm pump is use for auxiliary circulation ink supply, and the open DC ink reflow is used to ensure the sealing performance of both ends, effectively solve the problem of ink leakage of the scraper, thus ensuring the quality of the printed matter and the cleanliness of the machine surface.

- If the ink volume is too low, it will automatically alarm to avoid damaging the scraper and anilox roll.

- Automatic cleaning system for scraper and ceramic anilox roll, with ink return system, to reduce waste.

- Phase adjustment structure

- The printing phase is controlled by PLC, touch screen and electric digital 360 degree adjustment (both operation and stop can be adjusted) Order can be stored

- The printing plate roller can adjust the phase, return to zero and adjust the plate quickly, with high accuracy

- Automatic reset system after cleaning the printing plate during printing

- Electrically adjust the transverse device, and the adjustment distance is 10mm in total.

- Ink circulation

- Air pressure diaphragm pump, stable ink supply, simple operation and maintenance.

- Ink shortage alarm device.

- Ink filter screen to filter impurities.

- Stainless steel ink tank.

- Quick ink washing device.

- Vacuum transmission is adopted between units to improve printing effect.

- The paper feeding wheel of vacuum box adopts ceramic spraying wheel.

- The guide board is made of stainless steel to reduce the friction in the process of cardboard transportation.

- The air door is controlled by pneumatic and PLC.

- The bellows of the whole machine is connected and the suction is balanced, which is conducive to the fast and stable transportation of cardboard and improves the cardboard printing effect.

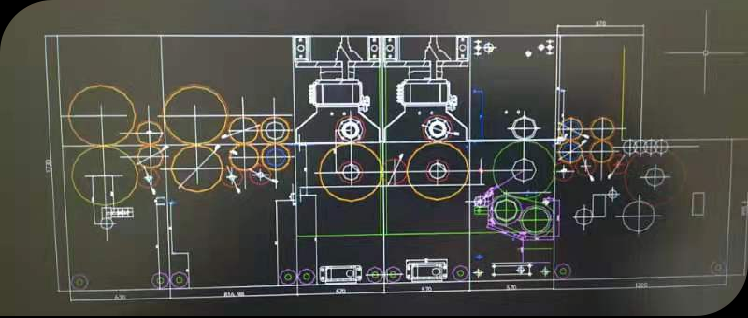

Slotting Part:

- Slotting unit adopt 8 shaft design, including pre-creasing wheel, creasing wheel, forming wheel and slotting knife disk.

- Adopt internal gear structure to adjust carton box height, it prevents lubrication oil not easy pollution carton box.

- Slotting Transverse movement

1) The slotting phase is adjusted by PLC, touch screen control and electric digital 360 degree. (Operation and stop can be adjusted)

2) Pre-pressing, forming line pressing and slotting position transverse movement are adjusted synchronously by linear precision guide rail and lead screw, and double anti-collision protection device is used for slotting tool base transverse movement.

3) The height adjustment of slotting box adopts electric four-knife synchronous adjustment.

4) Alloy steel is heat treated, grinded and trimmed, with sharp edge and high precision.

5) The alloy steel of slotting knife is heat-treated and grinded with good hardness and toughness, and its width is 7mm.

- Slotting phase and carton box height adopt computer and electric digital control.

- Pre-pressing wheel, pressing line wheel, slotting knife disk lateral movement adopt computer and electric digital control.

- Elastic slicing corner structure, three layer, five layer corrugated paperboard without adjustment.

- Slotting unit adopt gear to drive

- The slotting unit is placed on the guide rail and can be separated and opened from the whole machine during maintenance and cleaning.

- Slotting cutter base traverse structure, lead screw with guide rail, making the movement more flexible and accurate.

- The prepressing wheel, and the creasing line wheel are not easy to crush the cardboard after crimping.

- Automatic axial positioning of all tool holders.

- The clearance of all shafts is automatically adjusted.

- The slotting control panel is equipped with emergency stop button to ensure safety and avoid waste in emergencies.

Die Cutting Part:

- The servo motor is used to drive the die cutting roll and rubber cushion roll independently, and the closed transmission box is equipped with 6-level precision gear.

- The device can automatically cut the rubber pad, which can repair the rubber pad for many times.

- The rubber cushion roll and template roll are made of high-quality steel, and are calibrated by dynamic balance to increase the operation stability.

- The mold roll and rubber pad roll are automatically separated by the cylinder eccentric device under the non die-cutting state, which can reduce the load of the machine when it is empty, and effectively extend the life of the glue and the knife mold.

- The mechanical transmission rubber can move+20mm from left to right, and is equipped with a radial differential device, which can make the rubber roller wear evenly distributed, thus greatly improving the service life of the rubber roller.

- With a unique differential compensation device, no matter how the diameter of the rubber pad changes, the differential compensation device can make the Youli rubber roll slide with the template roll, so that the surface speed of the rubber pad is completely controlled by the knife mold operation and the die cut carton is completely consistent with the model.

- Waste conveyor belt

Folder Gluer Part:

- Paper receiving section:

- The main motor adopts frequency conversion speed regulation, the system has no noise, and the speed regulation is flexible and stable;

- Multiple groups belts are use for paper feeding, and each group of belts moves horizontally electrically, which is accurate and reliable;

- High grade electromagnetic clutch brake system is adopted, so that the paper feeding section can be controlled independently, and the operation is simple and convenient;

- The front paper feeding section can be adjusted electrically to meet the paper supply requirements of cartons with corresponding specifications, which is convenient and fast;

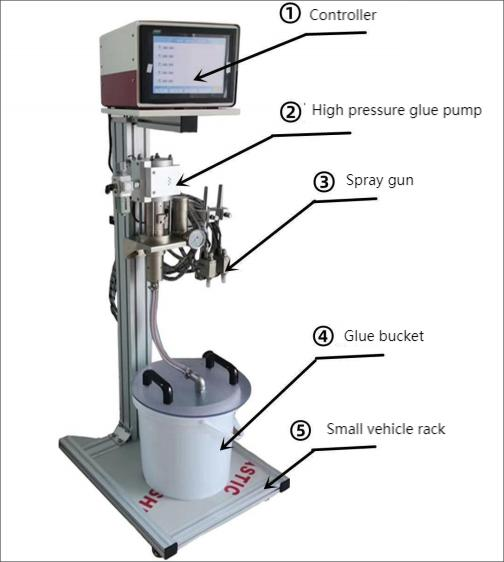

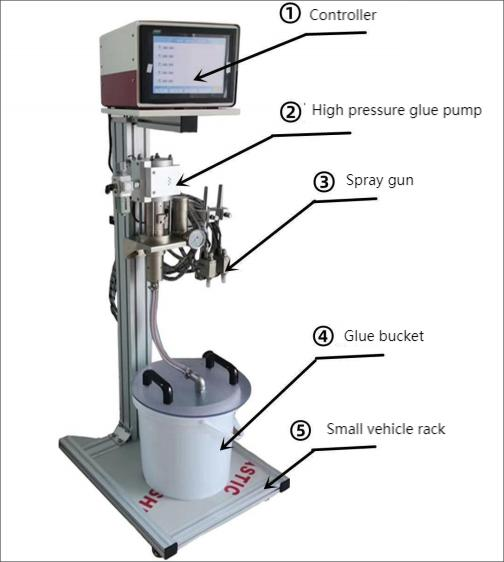

- The glue spraying method shall be adopted, and the glue shall be evenly applied without missing and saving glue. The amount of glue sprayed by the spray gun is adjusted by the computer, and the computer control speed is synchronized with the host.

- Install a glue pump to applied circularly.

- Gluing section:

- Adopt 3 point automatic spray gun glue system.

- Automatic glue spraying section adopts full computer control to automatically adjust the gluing position according to the size of the cardboard.

- The glue spraying width of the carton is 10-35mm, and the glue spraying width and method can be set by the computer.

- It can move left and right according to the box type glue gun.

- The paste amount can be controlled, the glue amount is stable, the capacity is large, and the maintenance is simple.

- All materials are made of pure stainless steel, which will never rust and will be resistant to various glues.

- Folding section:

- Linkage with the paper feeding section, frequency conversion speed regulation.

- The high friction belt is used to transport the cardboard, which is automatically folded, effectively avoiding the phenomenon of fish tail caused by different cardboard thickness or different belt tightness on both sides.

- The folding part is equipped with cardboard correction device, indentation correction device, which can effectively compensate and correct the phenomenon that the fold line of the slotting process is not in place, so as to avoid the generation of fish tail.

- Automatic stack counting output section:

- Adopt servo down type paper receiving system, which has high stability and will not damage the printed words on the carton surface and the carton surface. Select the corresponding stacking qty on the display screen, set the counted stacking qty, and set the qty range of 5/10/15/20/25 sheets.

- The glued carton will be clap, count, stack, sort and sent out automatically;

- The sun wheel is use to press paper, which is suitable for cardboard of various specifications and thicknesses;

- Servo control mode is adopted for counting and pushing, which is reliable, accurate and fast;

- The machine is equipped with a stepless differential device, which can effectively avoid the situation of fish tail when sticking the box.

- Emergency stop switch is equipped to avoid waste of cardboard in emergency and increase safety factor to ensure personal safety.

Main Electrical And Spare Parts List:

|

Printing Machine Unit

|

Folder Gluer Machine Unit

|

|

Contactor: Omron

|

Frequency converter: Delta

|

|

Button: Omron

|

Contactor: Siemens

|

|

Frequency converter:Schneider

|

Servo motor: Fuji, Japan

|

|

Touch screen:Siemens

|

Air switch: Siemens

|

|

PLC:Schneider

|

Touch screen: Delta

|

|

Ink motor: GPG(Taibang)

|

Reduction motor: Jiangsu

|

|

Phase motor:GPG(Taibang)

|

PLC: Delta

|

|

Knife disk motor:GPG(Taibang)

|

|

|

Servo motor:WKD Shenzhen

|

|

|

Vacuum motor:Baoding Hebei

|

|

|

Doctor blade: made in USA

|

|

|

Vacuum box: Fujian China

|

|

|

Anilox roller: Shanghai China

|

|

Transmission gear:

1. Main transmission gear

- The 20CrMnTi alloy steel is forged, tempered, carburized and finely grinded. It has six-level accuracy (the same level as the gear of automobile transmission box).

- Smooth operation, low noise, hardness HRC58-62, long life, can achieve long-term printing registration.

2. Key-free connection rings

- The use of keyless connection rings can make the shaft and gear seamlessly connected, and there will be no gap in the use of large torsion. It is more convenient to install and maintain, and can make long-term transmission accuracy high, so as to ensure the printing set accuracy.

Supplementary content:

- Slotting knife thickness is 7mm. Qingdao brand.

- Shanghai ceramic anilox roller.

- Slotting is 4 blade 6 roller 8 screw shaft model

- Die-cutting Anvil rubber pad is Depair brand.

- With ink & rubber roller / blade drawings and other required drawing.

- With needed accessories:

1) with extra unit of slotting blade 16 pieces

2) with extra 2 ink pump

3) with extra 2 encoder

4) with extra 2 relay.

5) with extra hand wheel and buttons

6) with one tool box for folder gluer machine.

- 30% advance payment by TT

- 65% before sending documents by TT,

- 5% after install machine by TT

If buyer need engineer, NORTH PACK factory must supply engineer.

Buyer need supply the round ticket, food, hotel and 100 USD per day salary.

120 days after receipt of advance.

![]()