Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 100%

| Model No.: 600-3 | Place of Origin: China |

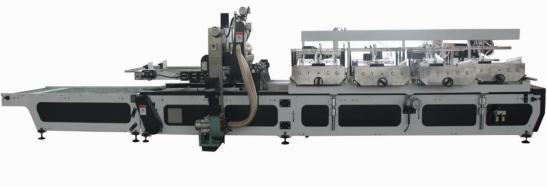

Partition Assembler Machine

Sample Picture Of Machine

Specification List

|

Item |

Parts name |

Qty |

Remarks |

|

1 |

Automatic Partition machine |

1unit |

Inserting : double-position; Sheets Composing: Decussation |

|

2 |

Sheet Delivery |

1 unit |

|

|

3 |

Pneumatic System |

1 set |

customer prepare air pump |

|

4 |

Electric System |

1 set |

PLC 、human machine interface 、 Servo control |

|

Name |

Brand |

Name |

Brand |

|

Servo Motor |

Schneider |

Vacuum pump |

Air-pump |

|

PLC |

Schneider |

Proximity switch |

SICK |

|

Servo Driver |

Schneider |

Roller motor |

Dedong Electric |

|

Inverter |

Schneider |

Cylinder |

AirTAC |

|

Touch Screen |

Schneider |

Solenoid valve |

F-tec |

|

AC Contactor |

Schneider |

Flow control valve |

SNS |

|

Reduction box |

APEX |

Clean air conponent |

SNS |

|

Draught fan |

Popula |

Oil-water separator |

SNS |

|

/Name |

/Unit |

/Data |

|

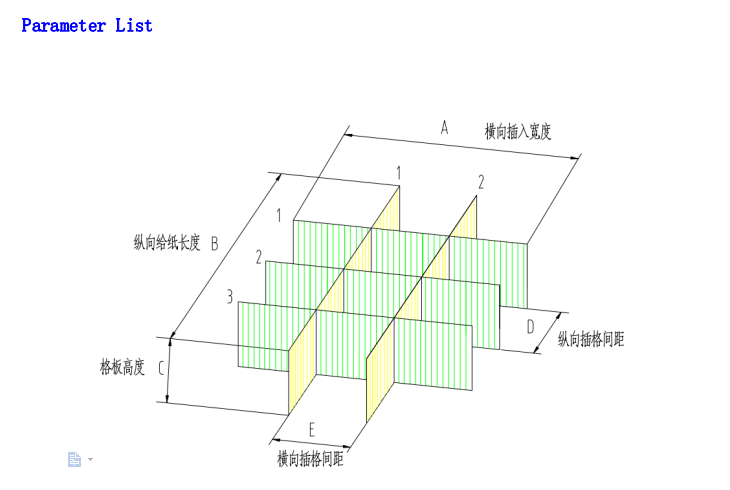

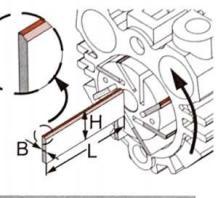

/ Horizontal inserting width: A |

mm |

120~900 |

|

/ Lengthways sheets length: B |

mm |

210~600 |

|

/Clapboard Height: C |

mm |

80~334 |

|

/ Lengthways clapboard distance: D |

mm |

20~500 |

|

Horizontal clapboard distance: E |

mm |

45-850 |

|

/ Lengthways sheets No. |

Piece |

1-6 |

|

/ Horizontal clapboard No. |

Piece |

1-29 |

|

/Carton thickness:G |

mm |

1.5~8mm |

Delivery and Warranty

* delivery time: around 35 days after received the advance payment

* warranty: 12 months from the date of acceptance of machine, only mechanical parts and for non-human damage, excluding electrical parts.

Machine daily maintenance

Maintenance of machinery and equipment is the daily work that must be carried out by operators to maintain the normal operation of machinery and extend the service life.

1. Three requirements for equipment maintenance

(1) Tidiness: equipment tools and accessories are placed neatly; The line and gas pipeline are complete.

(2) Cleaning: internal and external cleaning of equipment; Sliding surfaces, lead screws, gears, chain bearings, etc.Pay attention to rust prevention; No oil leakage, no water leakage, no air leakage and no electric leakage at all parts; Paper scraps and garbage shall be cleaned up in time.

(3) Safety: be familiar with the equipment structure and operating procedures, reasonably use the equipment and carefully maintain,equipment to prevent accidents.

2. Safety precautions for the person in charge of maintenance

(1) Before inspection and maintenance, understand and master the operation process of the machine before operation.

(2) Do not open the operation button box and electrical component box unless necessary for maintenance and inspection.

(3) During inspection and maintenance, all power supplies such as air pressure and electric power shall be cut off before operation.

(4) After the charged machine and motor are discharged, the operation can be carried out only after the temperature drops.

(5) Make sure that the power cables and wires are not damaged before operation.

(6) When replacing parts, use parts with guaranteed quality.

The surrounding environment of the machine should be regularly sorted out. Ignoring this point may lead to major accidents. Therefore, it is necessary to ensure the safety of the space around the machine and within the range of the operator's movement. In addition, it is necessary to ensure the lighting of the machine operation inspection, and pay attention to the damage of the wires and cables laid on the ground to prevent electric induction with other objects. Wipe the water, oil and other liquids on the ground surface daily to remove garbage and sundries.

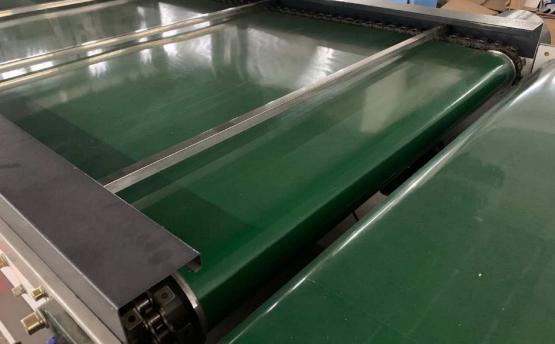

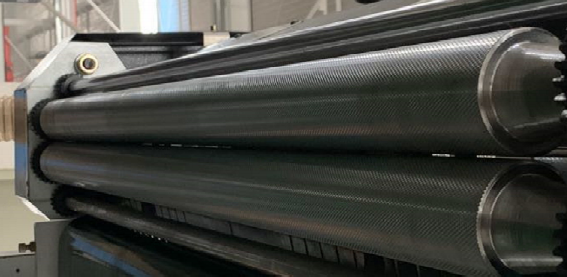

After rotating the traction roller every shift, check whether the synchronous belt of the traction roller operates stably. If the synchronous belt shakes seriously, adjust the adjusting bolt above the synchronous belt or check whether the synchronous belt is in good condition.

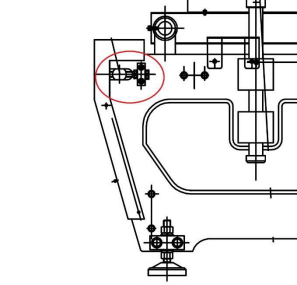

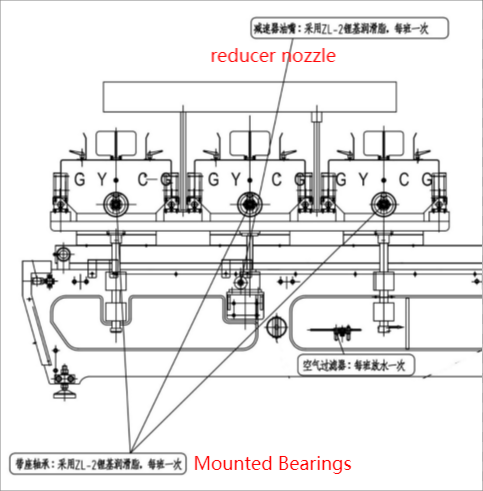

(1) As shown in the figure, the reducer nozzle and Mounted Bearings shall be lubricated with ZL-2 lithium base grease once per shift. The air filter discharges water once per shift.

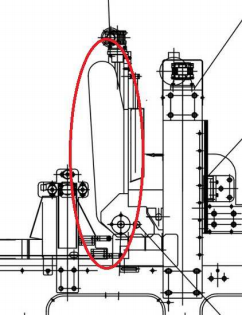

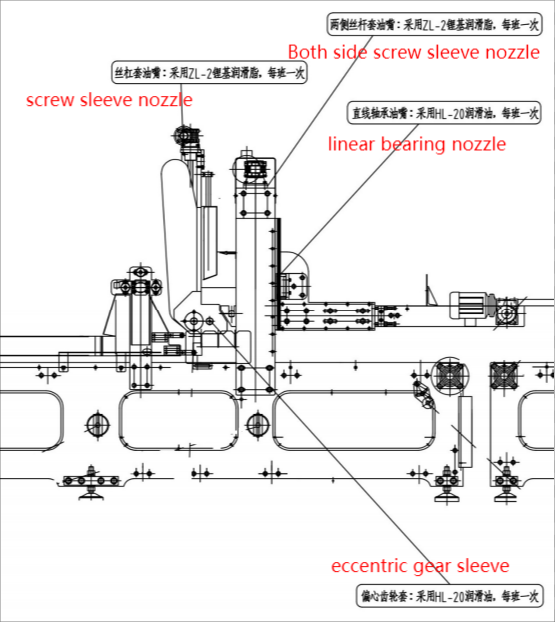

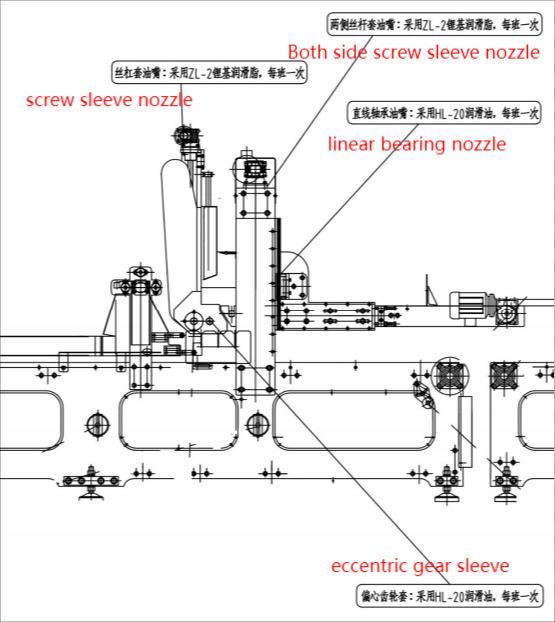

(2) As shown in the figure, the screw sleeve nozzle and the screw sleeve nozzle on both sides are lubricated with ZL-2 lithium grease, once per shift; The linear bearing nozzle and eccentric gear sleeve are lubricated with HL-20 lubricating oil once per shift.

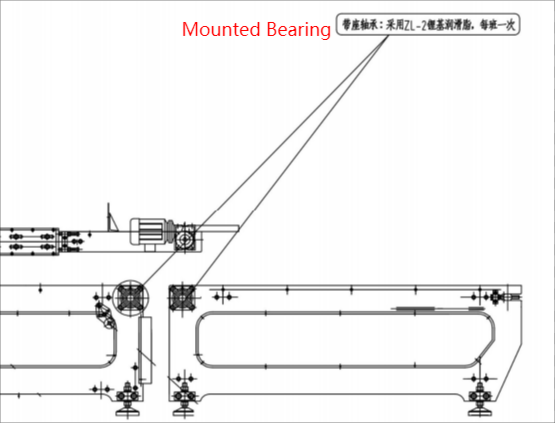

(3) As shown in the figure, the Mounted Bearing is lubricated with ZL-2 lithium base grease once per shift.

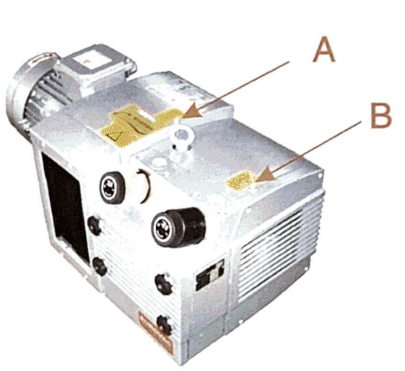

(4) Inject 5-7g lubricating grease at the marked positions of a and B every three weeks (when the vacuum pump is in operation)

![]()